About GobeacTool

Your Trusted Saw Blade Factory

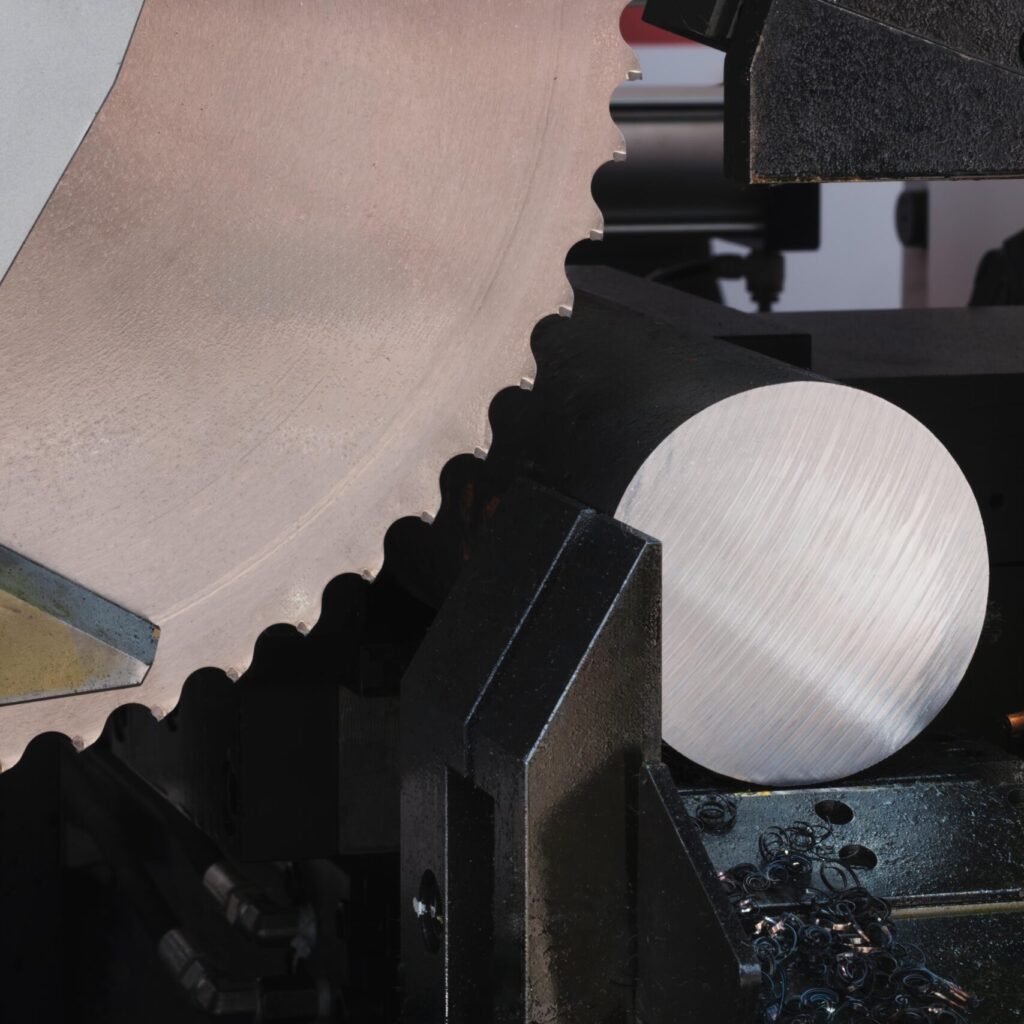

Gobeac Tools is a 17-year-old Chinese manufacturer of metal cutting saw blades, with an annual production capacity of 500,000 blades. We provide safe, reliable, and durable products to industries such as automotive parts, pipe manufacturing, construction machinery, and home building materials.Our tools are manufactured according to strict European Safety Standards for maximum reliability.

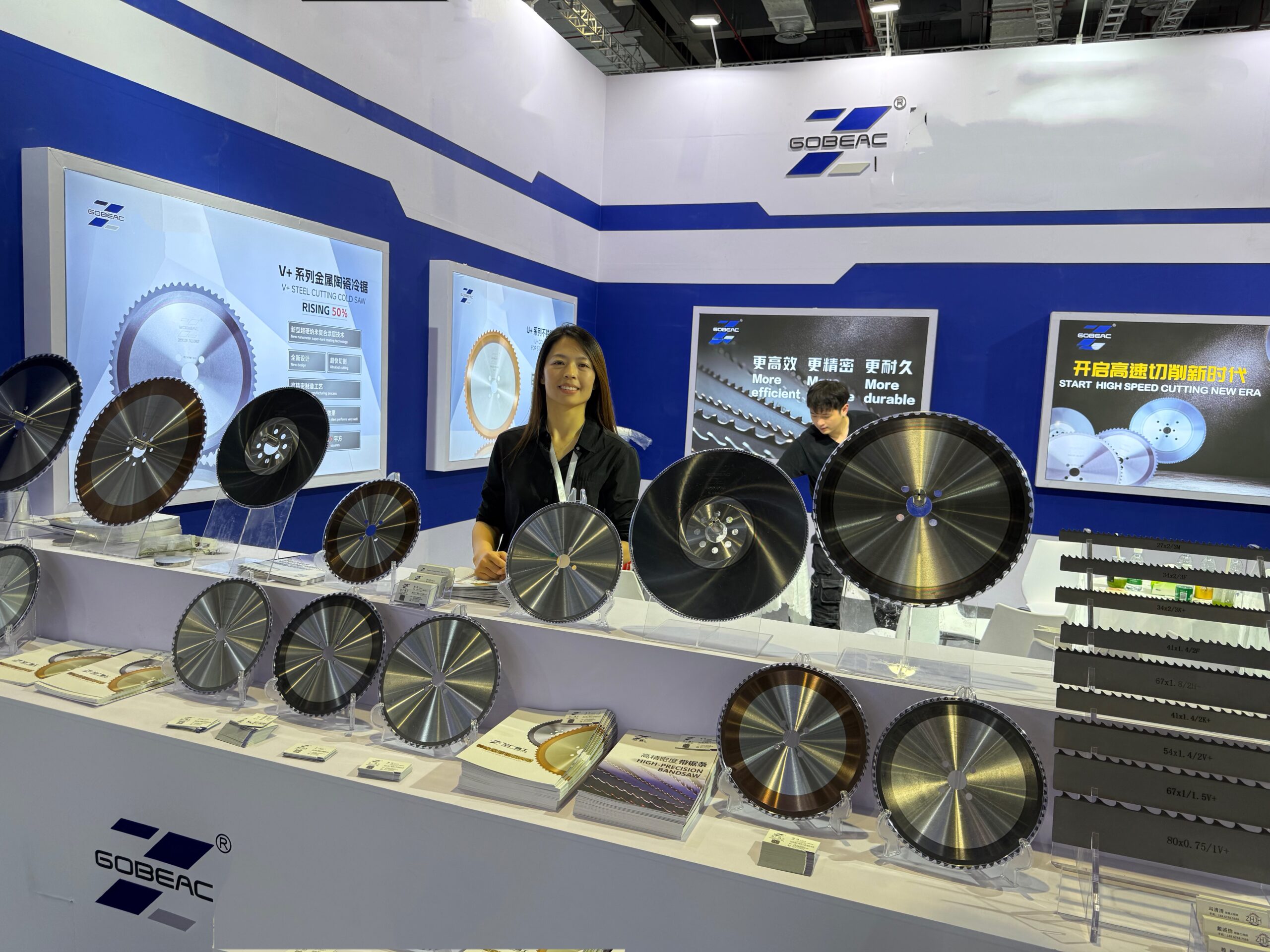

PRODUCT

Powering Your Industry

An overview of the workshops you offer and how they will benefit the visitor.

Why Choose GOBEACTOOL

Precision in Every Cut. Partnership in Every Deal.

Cutting-Edge Technical Expertise

With 50+ national patents and R&D investment 200% above industry average. Utilizing German CNC production lines to guarantee micron-level precision in every blade.

Rigorous Quality System

Implementing 16-step quality control process with raw materials sourced from Japan and Germany. Products certified to ISO 9001, CE international standards, exceeding industry service life by 30%.

Globally Verified Performance

Serving 60+ countries worldwide with annual export volume exceeding 2 million blades. Established stable supply partnerships with Fortune 500 companies.

Professional Customization

Supporting OEM/ODM services with prototype sampling in just 7 days. Providing end-to-end technical guidance from selection to after-sales.

Smart Manufacturing Advantage

Operating 600 automated equipment units with daily production capacity of 8,000 blades. Flexible manufacturing ensures standard quality even for small batches.

Sustainable Solutions

Employing eco-friendly production processes that reduce energy consumption by 25%. Offering blade refurbishment services to extend product lifecycle by over 50%.

Qualification Certificate

ask us

anything

Can we place small quantity orders as a startup company?

How long does it take from order to delivery for a custom-sized blade?

How do you ensure consistent product quality?

What if we are not satisfied with the products upon receipt?

Is it possible to visit your factory?

Client Testimonials

GobeacTool's factory workshop